Our team at Industrial Welding & Repair recently did an emergency project involving code welding & fabrication in West Deptford, NJ on a hot oil circulation heater for a client. Caught by our maintenance team servicing this chemical plant. Our crew noticed the lid temperature of the heater surpassed allowable temperatures. This meant that the flame produced by the burner was malfunctioning and instead of going down into the vessel to heat surrounding coils, was curling back up and accumulating at the top of the vessel. Therefore, damaging all steel walls and insulation protecting the lid.

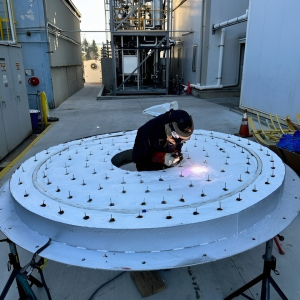

Upon inspection of the heater, we first saw that the inner wall was completely compromised. Following this we then realized the lid and whole outer wall of the vessel was warped due to the heat damage. In the heaters condition repair to the existing material was not an option. We proceeded to cut, grind, and weld new inner and outer walls. With the help of Sigma Thermal’s representative Jim Reynolds we worked to replicate OEM specifications while ensuring future reliability and the customers need to be back up and running.

Details of Code Welding & Fabrication in West Deptford, NJ

- Surrounding coil wall

- Outer vessel wall

- Lid mounting flange

- Burner

“To Whom it May Concern,

Please accept this letter of recommendation for Pierre Rai and his crew with Industrial Welding and Repair, Inc. for services that required the rebuilding of a thermal fluid heater located in West Deptford, NJ. Sigma Thermal, Inc. is the OEM for this specific piece of equipment and because of a catastrophic failure of the unit and a lack of time allowing for a replacement to be purchased, built and installed, we worked with our customer and their preferred sub contractor of choice, IWR to provide a rebuild of the heater. The scope of work included the demolition of the damaged components, prepping of the remainder of the heater for the new components to be installed, rigging and lifting, welding, cutting, grinding, insulation installation, and modifications as recommended. This project was originally estimated to take about 5 days, but because of the complexity of the install, this ran into a weekend, which IWR remained for, continuing the project with little notice. The quality of their work was very good, and they strive for “doing it right”, it is with no hesitation that I would use them again for projects that we have within the areas that they service.”

– Jim Reynolds of Sigma Thermal