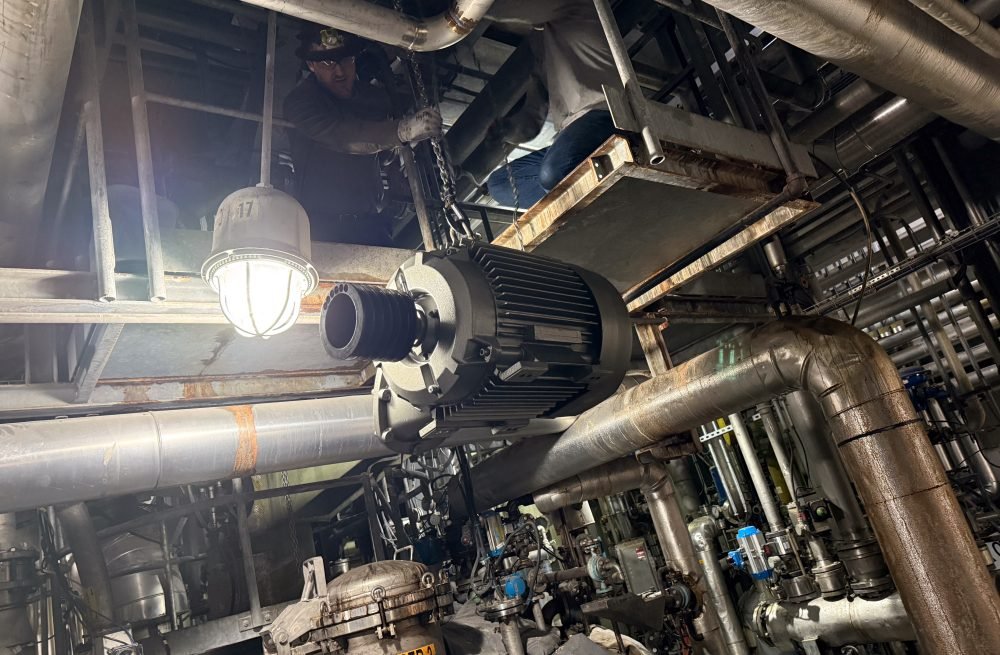

Our maintenance team at Industrial Welding & Repair recently completed a project involving a motor replacement in New Jersey for a chemical plant. Our client wanted to replace a motor that drives one of their reactor agitators due to an electrical problem with the motor.

Our team had to asses how to safely and efficiently replace this 100hp motor through obstacles and offset rigging points. First, we removed any equipment such as guards, belts, and brackets attaching the motor to the gearbox. After, we set up 2 trolleys with chain folds on separate beams in order to safely transfer the load of the bad motor around obstacles. In this instance we had to remove a railing from a platform surrounding the reactor. By doing this we allowed ourselves a clear pathway to the ground. After the motor was on the ground, we attached the replacement motor to the chain fold allowing us to go back up to the reactor. We lifted, transferred, and set the new motor. Once in place we aligned the motor and gearbox shivs. We do this to ensure that we are protecting both the motor and the gearbox from misalignment and vibration which could cause premature bearing failure in the equipment. Finally, we added new belts, greased the motor, and put back any brackets and guards. By doing all these steps we keep our customers new equipment in the best possible condition and we can focus on future preventative maintenance required to keep downtime to a minimal.

Details of Motor Replacement in New Jersey

- Removed old motor

- Installed new motor

- Removed old belts

- Installed new belts